Application of Management Reliability Index for Water Distribution System Assessment

Article information

Abstract

Indexes of safety, restoration, damage impact, and management reliability were developed to assess reliability of drinking water distribution networks (DWDNs) management. The developed indexes were applied to evaluate the reliability of the pipeline management stage during unexpected mechanical and hydraulic accidents of components. The results were used to support the decision-making process in effective management and maintenance by enhancing the administrator’s system understanding and by helping to create appropriate maintenance and management policies. The results of this study indicated that application of a management reliability index to assess DWDNs reliability may help create a more effective plan for establishing DWDNs management and maintenance.

1. Introduction

Drinking water distribution networks (DWDNs) have evolved to become an intricate and extensive system, which are consists of pipelines, pumps, and valves. The complexity of the system made it more vulnerable to the dynamic urban environments. The system components are interrelated each other and influenced by other components. Proper understanding and analysis of the entire system are required to ensure efficient management and maintenance. The analysis of factors affecting depreciation of the waterworks service quality and the establishment of countermeasures for DWDNs reliability are becoming important issues for a DWDNs administrator, especially in cases when one of the waterworks components, such as pipelines and pumps, are not properly functional [1].

DWDNs with appropriate design and careful maintenance are supposed to tolerate an unexpected accident among its components and be able to keep sustainable water supply. However, most previous studies attempted to understand and analyze the DWDNs’ component in its design stages. Therefore, few studies have been done on its operational management and administration. For efficient management and maintenance, reliability evaluation of the DWDNs is critical because of unanticipated mechanical and hydraulic accidents in the operation of the DWDNs that might diminish the system’s safety and stability.

In this study, we developed an management reliability index (MRI) for the evaluation of management reliability by analyzing target pipeline burst, leakage repair register, waterworks’ geographic information system (GIS) data, and the other related data. The MRI includes factors of safety, restoration, and damage impact in DWDNs by collecting and organizing the target area’s pipeline burst, leakage repair register, waterworks GIS, and required quantity data. MRI is then used to assess application the management reliability of the operation of DWDNs.

2. Materials and Methods

2.1. Research Area

Fig. 1 shows the map of water distribution network in S city (city name is not shown by the request of the city). The DWDNs of the target area had a block structure and had been keeping GIS data, leakage repair register, and other related data for the high accuracy research. It has 2,196 connections, total 16,374 m of water distribution pipeline, 100% of water supply to each household, and 867,000 m3 per year in water supply capacity. The area is composed of a business and residential area.

A medium sized block (we call this as ‘C block’), as shown in the Fig. 1, was selected for this study, for which we considered the amount of available data and degree of isolation from adjacent blocks. The C block includes a distribution reservoir. Emergency connection pipes between adjacent blocks and target areas were added to carry out simulation with increased reliability.

2.2. Development of management reliability index

The developed indexes were safety index, restoration index, and damage impact index, all of which is integrated in to the MRI.

2.2.1. Safety index

The definition of safety is the improbability of pipe burst in the jth pipeline, which can be seen as Eq. (1). The safety index assesses how safely the waterworks system is being operated.

where

αj : safety index of the jth water pipeline,

α̂j : burst probability of the jth water pipeline,

j : 1, ···, n (n = total number of water pipeline).

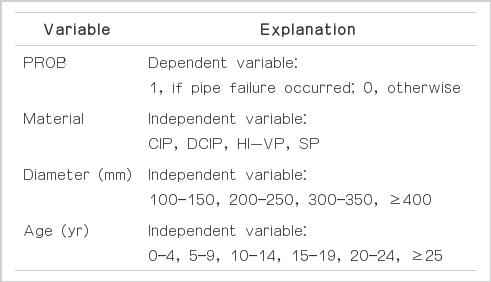

In order to assess the safety of the C block, GIS and burst data were collected, organized, and then analyzed logistic regression analysis. The logistic regression analysis could be done even when the dependant variable was a qualitative variable. The categorical data may be chosen as an independent variable using a dummy variable in the method. It, hence, differs from general linear regression analysis. This study used incidence for the pipe burst as a dependent variable and incorporated all categorical data as independent variables for the logistic regression analysis. The commercialized statistic package SPSS ver. 18 (SPSS Inc., Chicago, IL, USA) was used for the analysis. Table 1 shows the organized the variables used in the analysis.

2.2.2. Restoration index

The definition of restoration is “how quickly the system can return to its normal functional status after an accident”. The mathematical expression for restoration is shown at the Eq. (2).

where

βj : restoration index of the jth water pipeline,

β̂j: accident restoration time of the jth water pipeline,

Tt : unit time required for restoration of the broken water pipeline.

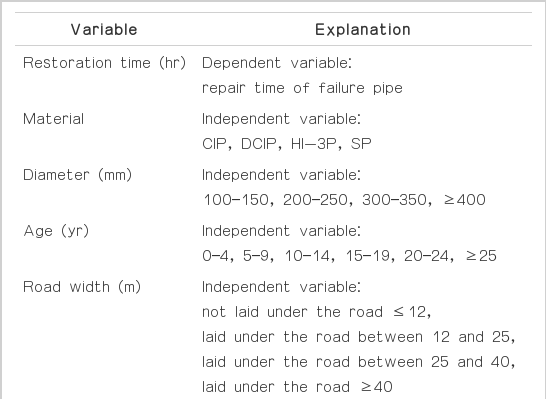

The GIS data and pipe burst restoration time were collected, organized to be used as variables in the multiple regression analysis. The general multiple regression analysis was used to find the pipe burst restoration time by obtaining complex functional relations out of one dependent variable and several independent variables. This method draws a mathematical model from collected data to make relationship between each variable. The mathematical model may be used to predict the value of dependent variable.

This study took the pipe burst restoration time as the dependent variable. The classified data of the independent variables were used as dummy variables to do the multiple regression analysis. In the analysis, the commercialized statistics package of SPSS ver. 18 was also used. Table 2 shows the details of the variables used in the analysis.

2.2.3. Damage impact index

The definition of damage impact is significance of the system’s accident. The damage impact index is the scale of damage caused from system’s accidents as shown in the Eq. (3). It is related to the extent of water deficiency damage in a waterworks accident.

where

γi : damage impact index of the jth water pipeline,

i : ith node,

m : total number of nodes,

Di : water demand of the ith node,

Qiavl : available water flow of the ith node.

In order to evaluate the damage impact in the target area, the GIS and required data were collected and organized. The data were further used for Pressure Driven Analysis (PDA) simulation using EPANET.

The damage impact from an accident of each water pipe was obtained using the EPANET PDA simulation by means of combining the concepts of unintentionally isolated area [2] and segment [3] to estimate the water deficiency due to pipe bursts in the isolated area considering the practical pipe network condition. The segment is a set of pipeline that is isolated simultaneously with the shutdown of sluice valve. The unintentionally isolated area is the region which is not included in the segment while water supply is interrupted for the segment’s isolation. Therefore, it is included in calculation of the waterworks’ burst damage.

2.2.4. Management reliability index

MRI is a combination of safety, restoration, and damage impact indexes as shown in Eq. (4). This index includes overall assessment of the current management condition in each water pipe within the specific water distribution areas.

where

MRIj : MRI of the jth water pipeline,

αA,βA,γA : arithmetic mean of safety, restoration, and damage impact, respectively.

The degrees of safety, restoration, and damage impact on management reliability were presumed to be the same in this study.

3. Results and Discussion

3.1. Safety Index

The noble safety index was applied to assess the water pipeline safety of C block in the DWDNs of S city, which was composed of 4 small blocks. The block had 9 cases of pipeline bursts over a period of two and a half years. The amount of data was insufficient for logistic multiple regression. The subject area was expanded into 68 small blocks of ‘S’ and ‘J’ blocks of city S to make up insufficient data. The quantity of data for waterworks pipeline bursts was extended into 219 cases. The safety index was obtained using Eq. (1) and the pipe burst probability calculated through the logistic multiple regression analysis. The produced results were classified into excellent (grade 1), good (2), fair (3), poor (4), and critical (5).

Cast iron pipe (CIP) Pipe with diameter ranged from 100 to 150 mm and with age over 25 years had the highest pipe burst probability in the C block. Ductile cast iron pipe (DCIP) pipe with diameter over 400 mm and with age ranged from 15 to 19 years had the lowest pipe burst probability. The average pipe burst probability was 9.0% per observed periods while pipe burst probabilities range from 2.8% to 24.1%. The average safety index was 91.0%. The old CIP pipes with small diameters had the lowest safety index of 75.9% and vulnerable to the accidents with the highest probability. Such pipes need to be exchanged or rehabilitated to lower the possibility pipeline burst accidents.

The results of the safety index are shown in Fig. 2. In the C block 81.1% of the pipeline was graded in the rank of 1 or 2 with a low probability of pipe bursts while 13.9% ranked to be 4 or 5 with a high pipe burst probability. This suggested that the safety in terms of the safety index of pipeline burst accidents in this area is relatively satisfactory in the area.

3.2. Restoration Index

The restoration index was applied to assess the pipeline restoration of C block. From the safety index, 212 valid restoration time data in the 219 cases of pipeline burst data were collected for the analysis to calculate the pipeline burst restoration time using multiple regression analysis. The restoration index was extracted through assigning a pipe burst probability calculated through multiple regression analysis to Eq. (2). The results obtained were ranked as excellent (grade 1), good (2), fair (3), poor (4), and critical (5). In C block, a pipe with diameter ranged from 100 to 150 mm and buried in a road with a width less than 12 m had the shortest pipe burst restoration time while pipeline buried in a road width of 40 m or higher with a pipe diameter of 400 mm and higher had the longest pipe burst restoration time.

The average restoration index was 22.5%. The pipeline with a pipe diameter of 400 mm or higher in a broad road had the longest pipe restoration and the lowest restoration index of 14.3%. Since pipelines with low restoration indexes are in the areas of slow pipe burst restoration, the accident location detection, restoration equipment and pipe burst accident management expert training need to be improved to enhance the accident restoration time in the future.

The results of the restoration index are shown in Fig. 3. Since 90.6% of the pipe burst restoration times were in the above average rank of 3, 4, and 5, the restoration pipe bursts in this region were relatively unsatisfactory in C block.

3.3. Damage Impact Index

The developed damage impact index was applied to assess the pipeline damage impact of C block. The water distribution pipeline GIS and required quantity data were collected and processed for EPANET PDA simulation. The analysis results were used to calculate the pipe burst water deficiency. The supply quantity in normal condition was calculated to assign the damage impact index without the results of a pipe burst-induced water deficiency. Fig. 4 displays the pipeline analysis results through PDA simulation using EPANET in the normal condition.

The water supplied in C block was 10,251.67 m3/day, which was used to calculate the damage impact index in various pipe burst conditions with PDA simulation results using the EPANET. Individual segment, each of which is isolated simultaneously when an adjacent sluice valve is closed, were selected and analyzed to reflect the actual pipe network condition in a pipe burst in PDA simulation using EPANET. C block contains 58 segments and two node-segment that solely consisted of nodes. The water shortage of the burst segment was obtained using pipe burst simulation analysis on the basis of the burst pipe’s segment. The water deficiency shown here presents the water deficiency in the segment due to node isolation. The indirect water deficiency presents the deficiency of water due to the decreased water pressure in the nodes not included in the segment and unintentionally isolated areas.

C block has an average water deficiency due to pipe burst of 1,230.90 m3/day and the highest water deficiency was 10,251.67 m3/day. The pipelines directly connected to the water distribution reservoir and segments 13 and 15 area in a pipeline network in tree type had the largest water deficiency due to pipeline burst. The segments 2, 12, and 31 area at the DWDNs’ ending tip region barely had any water deficiency due to pipe bursts. Therefore, pipes 119 and 122 included in the segments 13 and 15 area with the largest water deficiency due to pipe bursts were estimated to be significantly influenced due to C block’s water deficiency. The water deficiency damage in segments 13 and 15 needs to be ameliorated in future development of DWDNs’ management and maintenance plans.

The damage impact index was obtained by assigning the calculated water deficiency through PDA simulation using the EPANET and Eq. (3). The results obtained were ranked as excellent (grade 1), good (2), fair (3), poor (4), and critical (5). The average damage impact index was 12.0%. Pipelines directly connected to the water distribution reservoir and pipelines composed of a tree-type network had the highest damage impact index of 100.0%, which revealed that they had the largest damage from pipe burst accidents. Due to the significant damage caused from pipe bursts, future plans, such as pipeline preparation, additional installation of sluice valves, and emergency connection pipes, would be necessary to remedy the water deficiency in pipelines with high damage impact index values.

The results of the damage impact index are presented in Fig. 5. In C block, 83.9% of the pipelines were ranked as 1, which is a small scale of water deficiency in the case of pipe bursts. Therefore, the water deficiency during pipe bursts was relatively satisfactory in this block.

3.4. Management Reliability Index

MRI developed to assess the reliability of C block in the DWDNs was supposed to be a noble decision-making tool for the efficient management and maintenance. The noble MRI was used to assess the management reliability of pipelines. The MRI incorporating all the indexes of safety, restoration, and damage impact was obtained using Eq. (4), which takes each index’s arithmetic average divided by the value of the indexes.

C block displayed an average MRI of 3. The cases of long tree network pipelines with high pipe burst probability and long restoration time had the lowest management reliability of 2.3, which revealed the unsatisfactory management and maintenance of these pipelines. Effective management and maintenance plans are necessary in the future in areas with low reliability to improve the necessary areas. Fig. 6 is the values of each index divided by the arithmetic mean. The MRI shown in a dark and thick line in this graph is influenced by safety, restoration, and damage impact indexes. Thus, if one or more of safety, restoration, damage impact indexes shows a very big or very small value, it is seen that the MRI depends on the index. Especially, since in the target area of research, the fluctuations of restoration and damage impact are greater than that of safety, it is judged that they are having a great impact on the outcome of the MRI.

The MRI is displayed on the GIS as shown in Fig. 7, and is categorized as excellent (grade 1), good (2), fair (3), poor (4), and critical (5) in the order of increasing satisfaction. The pipelines expressed with dark and light line reveal areas with high and low management and maintenance reliability, respectively. Therefore, pipelines presented with light lines require plans for effective management and maintenance.

4. Conclusions

Indexes of safety, restoration, damage impact, and management reliability were developed in order to assess the DWDNs management reliability. The developed indexes were applied to evaluate the reliability of the pipeline management stage during unexpected mechanical and hydraulic accidents of components. The results supported the decision-making process in effective management and maintenance by enhancing the administrator’s understanding of the system and by serving as a tool to create appropriate maintenance and management policies.

As a result, safety index evaluated that the pipes showing the highest probability of pipe failure, such as small diameter, old laying years, and CIP, were dangerous. Pipes with these characteristics were considered when planning for the future replacement and rehabilitation. Restoration index evaluated that the pipes showing the large diameter and large road width take long repair time. To advance the repair time, it is necessary that equipment for detection of failure position and failure repair are improved and professional of pipe failure management are trained. Impact index evaluated that pipes were large damage of water shortage. The pipes were linked directly to the reservoir and were combined tree pipe network. In order to decrease large damage of water shortage in failure condition, it is necessary that the pipes of two line, control valves or connection pipe of emergency are additionally installed.

And safety, restoration, and damage impact were combined, a MRI was developed and applied to the target pipes of the research. As a result of application, it turned out to be adequate for showing the reliability of operation and maintenance of water pipes. And yet, the MRI developed in this study was calculated by presuming the weights of safety, restoration, and damage impact are all the same. However, depending on the status of water pipes and of the operation management of water pipe networks, the conditions of safety, restoration, and damage impact may differ. Thus, to develop a generalized MRI, an additional study on weights on safety, restoration, and damage impact will be necessary. Furthermore, the application of systematical standards in the beginning construction phase of the data will enable a variety of accurate data to be collected and, therefore, allow the proposed index to be utilized in the DWDN management and maintenance plan with more accurate results.

Acknowledgments

This subject supported by Korea Ministry of Environment as Projects for Developing Eco-innovation Technologies (No. GT-11-G-02-001-1).