The effect of ensiling and alkaline pretreatment on anaerobic acidification of Napier grass in the leached bed process

Article information

Abstract

The characteristics of feedstock are important to the biocatalyst-based processes. Herein the effect of ensiling and alkaline pretreatment on acidification of Napier grass in anaerobic leached bed reactors was investigated. The results depicted clearly that grass preparation affected its chemical properties and leaching ability differently. After pretreatment in 3.0% of NaOH, lignin was reduced significantly by 50.1% to 68.0%, while less deterioration was found for ensiling. About 18.9% to 54.1% of the produced soluble chemical oxygen demand (SCOD) of these biomasses was increased subsequently compared to 0.102 kg SCOD or 0.56 kg SCOD/kg VSadded of raw grass digestion. However, about 3.3% of SCOD was reduced after the ensiling. An extension of biomass soaking time and heat supplementation under alkali-thermal conditions of raw grass promoted more production of SCOD for 18.9% to 29.9% and 54.1%, respectively. While about 45.5% to 54.4% of SCOD was increased for alkali-thermal pretreated residue. The solid content and lignocelluloses were changed differently and accordingly with treatment conditions. Similar profiles of leachates contained mainly acetic acid were obtained. These results confirm the beneficial application of alkaline soaking and ensiling as a pretreatment method to enhance the solubilization of grass biomass under the leached bed acidification process.

1. Introduction

Lignocellulosic biomasses i.e., crops, grass, or agro-industrial solid wastes and residues are potent resources for bioenergy production via the carboxylic fermentation platform of anaerobic digestion [1]. However, anaerobic digestion of these solid feedstocks is naturally complicated when compared to the liquid phase. Biomass solubilization under hydrolysis-acidification is considered the main limitation [2]. In the case of solid waste biogasification, the development of digester configuration, mainly the two-stage process, is still a practical strategy. This digester had been proposed firstly by Poland and Gosh in 1971 [3]. The two separated stage digester promotes more optimal growth conditions for each trophic group of microbes involved in acidogenesis and methanogenesis. The first stage digestion is proposed principally to the solubilization of grass into soluble products. Now the anaerobic leached bed reactor (LBR) has shown increased interest to apply for acidification of lignocellulosic feedstock [4].

For several decades, many efforts have attempted to regulate the biomass solubilization in the hydrolysis-acidification [5]. It was found that the retarded fractions mainly are lignin and crystalline cellulose [6]. Shah et al. [7] reported that lignin content of the biomass was varied according to the type of feedstock, i.e., 10.0% in peanut, 15.0% in raw paper, 23.0% in almond, and 26.0% in kallar grass. While about 3.9% to 12.3% of lignin was also found in Napier grass [8, 9]. This was considered as the main obstruction of rapid solubilization in anaerobic digestion. In order to regulate grass solubilization and increase acidification, various pretreatments employ physical, chemical, and biological strategies, i.e. mechanical shredding, soaking in acidic and/or alkaline solution, enzymatic addition have been studied [10, 11]. Besides those methods, alkaline pretreatment provokes the beneficial production and lignin destabilization over the other ones [11, 12]. For example, Barlianti et al. [12] found that the pretreatment of oil palm fruit brunch and fronds in 1.0% to 10.0% sodium hydroxide (NaOH) solution able to decrease lignin content by 47.3% and 37.8%, respectively. While about 83.7% to 87.3% of lignin in sugarcane bagasse was removed after alkali-thermal process with 1.5% to 2.0% of NaOH [13]. A similar finding was reported by Chaiyapong and Chavalparit [14], they found that Acacia leaves waste digestion increased about 2.0 times after alkaline soaking when compared to the non-pretreated leaves. Despite the regulation of biomass solubilization, the choice of pretreatment method also plays an important role in the efficient operation of anaerobic digester [15]. Sambusiti et al. [16] reported that not only more production of methane gas was promoted by 25.0% higher in between alkaline pretreated and non-pretreated sorghum forage, but more stability of digester was also observed.

Pennisetum purpureum Schumach, known commonly as Napier grass, Elephant grass or Uganda grass, is a perennial tropical grass species [9]. This grass is planted worldwide principally for animal feed. With high biomass productivity and ability to harvest all year long, Napier grass is a high potential feedstock for bioenergy and bio-based products production [17]. Practically it has been observed that grass harvesting is problematic sometimes, particularly in the rainy season of Thailand, when it is quite difficult to conduct field operations. Therefore, grass silage is an appropriated option able to reduce the cost of feedstock preparation and supply sufficiently raw material for biogas production plants. Grass ensiling is a simple preservative method implemented practically to biomass in order to extend its storage time. Four steps of ensiling can be found [18]. A short aerobic respiration period of the remaining oxygen occurs initially and turns properly to anaerobic one where fermentation of lactic bacteria is promoted. At the end of this step, the pH is normally lowered to approximately 4.0 [18]. Ensiling is a biochemical cascade process which may significantly impact the biomass characteristics and then affect consequently the post degradation and methane production in particular [19]. Therefore, in this study, the effect of ensiling and alkaline soaking as a pretreatment on acidification of Napier grass in the anaerobic leached bed process was investigated. Grass solubilization, total volatile fatty acids (tVFA) production and leachates’ profiles of raw, silage, pretreated samples, and its residue were focused on mainly.

2. Materials and Methods

2.1. Grass Samples

Four types of samples including raw grass, ensiled grass, alkaline pretreated grass, and residue were leached separately in lab-scale LBRs. These grass biomasses were harvested originally at the same age of two months and the same field located in Saraburi. After the harvesting, raw grass was shredded mechanically to the size of around 0.5 cm to 1.0 cm and promptly kept in a temperature-controlled room (4.0°C). For ensiling, it was processed and supported by Lek-uthai company. Practically, about 100 kg of fresh grass was packed in a vacuum plastic bag and stored in mesophilic condition for three months [18]. For the alkaline pretreated samples, about 3.0% of sodium hydroxide was applied [14]. Grass samples were soaking in an alkaline solution at mass fraction of 10.0% for 24.0 h and 48.0 h. It was then diluted with tap water and its pH adjusted to be 7.0 to 7.5 and used as feedstock. For the alkali-thermal process, an hour-soaked sample was then heated in an autoclave (at 121.0°C, 103.4 kPa) for 30.0 min. In addition, grass leached residue, the left-over grass biomass after the leaching process of LBR fed with raw and silage biomass, was also studied for alkaline re-treatment. Similar operational conditions were constantly controlled.

2.2. Reactor and Inoculation

Anaerobic LBR each with 14.2 L were set-up. This acrylic made reactors, sized 20.0 cm diameter and 40.0 cm height of the cylindrical digestion part and 15.0 cm height of the funnel drainage part were connected to the peristaltic pump for liquid feeding and recirculation, as well as a gas counter for the produced gas measurement. Each LBR was loaded separately with different grass samples mixed with dairy cow manure as a seed at the volatile solid fraction of 20.0%. Circular high porosity plastic balls sized 3.3 ± 0.2 cm was also mixed with the substrate in order to prevent clogging. All the experiments were conducted at ambient condition where temperature ranged between 24.4°C to 30.6°C.

2.3. Experimental Conditions

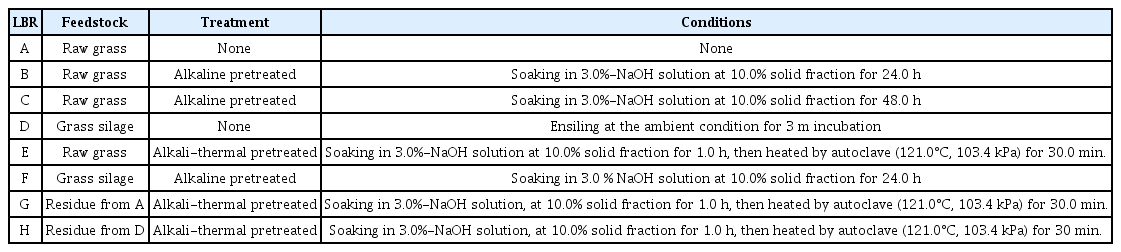

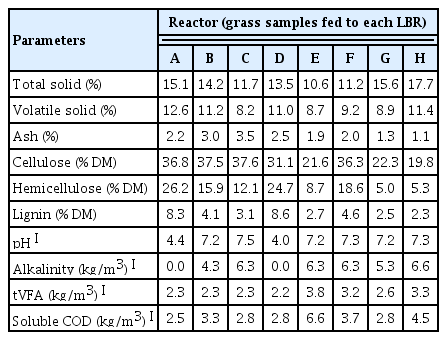

Two sets of experiments were conducted in four LBRs. For Exp-1, raw grass biomass with the different treatment conditions was studied. These were raw Napier grass (reactor A), alkaline pretreated grass by soaking in 3.0% of NaOH for 24.0 h (reactor B), 48.0 h (reactor C) and grass silage in reactor D. For Exp-2, ensiled grass with alkaline pretreatment at a soaking time of 24 h was loaded to reactor E, while raw grass biomass with alkali-thermal pretreatment was loaded to reactor F. In reactor G and H, grass residues from reactor A and D (Exp-1) were retreated in thermal-alkaline conditions and loaded to each tank. In practical, the pretreated grass biomass with neutralized condition was mixed with manure and loaded to each LBR. Initially, tap water was continuously recirculated for 3.0 h in order to ensure the saturated biomass bed was maintained. Then, the liquid phase was added by tap water to constant volume of 4.0 L. This leachate was recirculated hourly for 15.0 min per cycle throughout the experiment and in all reactors. These LBRs were regularly diluted at 3.0 d-intervals. In each tank, about 18.0 L of acidic leachate was similarly obtained. Practically, tap water was used to dilute the leachate by 50% replacement. About 1.2 kg of grass biomass was started in each LBR excepted for F and G. In Table 1, all experimental conditions used in this study are summarized.

2.4. Analysis and Interpretation

The operational and control parameters indicated the overall performance and stability of the digesters were routinely monitored. In practice, each experiment was operated for four weeks. Leachate samples were collected every 3.0 d for analysis in such parameters as pH, alkalinity (Alk), tVFA [20], total (TCOD) and soluble (SCOD) chemical oxygen demand [21]. At the end of each batch, solid and lignocellulosic contents of solid residue were determined following the standard [21] and Van Soest procedures [22]. Produced biogas and its composition, as well as volatile fatty acids composition (VFAs) or profiles as of acetic acid (HAc), propionic acid (HPr), butyric acid (HBu), iso-butyric acid (i-HBu), valeric acid (HVa), and iso-valeric acid (i-HVa) in leachate, were analyzed using gas chromatography (Shimadzu model). Two different detectors, thermal conductivity and flame ionized detectors were applied for biogas and VFAs analyses, respectively. To compare the solubilization of biomass, the determination was calculated based on the produced SCOD per TCOD. Whereas, hydrolysis was calculated from CODVFA generated per SCOD.

3. Results and Discussion

3.1. Feedstock Characteristics

The basic characteristics of grass samples used in this study are shown in Table 2. It was found that fresh Napier grass contained about 15.1% of TS, of which about 83.7% was volatilized. An elemental analysis depicted that this two-month age cut grass contained 43.3%, 4.7%, 49.4%, and 2.7% of C, H, O, N, respectively. After the ensiling, the decrease of TS and VS to approximately 10.5% and 12.7 % were observed, respectively. This loss had been reported similar to the previous works [23]. In fact, the volatile fractions increase simultaneously during biomass ensiling and have been volatilized during the drying of silage. Porter and Murray [23] reported that about 6.1% to 9.7% of TS in grass silages was reduced via volatilization of compositions like fatty acid, ethanol, and lactic acid. Much effort has been made to minimize the variation. The correction factors by mathematic calculation equations have been proposed. The results also show that volatile solid fraction in pretreated grass and residues were reduced significantly from 83.7% and 81.6% in raw and silage biomasses to 70.4% to 78.6% of the pretreated ones. This might be that the solubilization of the ready to be degraded substance was already leached. The organic matter was solubilized generally from the solid phase of biomass into liquid leachate. However, after the thermal treatment, a higher volatilized fraction was promoted. A similar content of fixed solid or ash was observed in all samples. These were 2.5%, 2.5%, 3.0% to 3.5% and 2.6% to 3.2% for raw, ensiled, alkali-pretreated, and residue biomass, respectively.

For lignocellulosic biomass, it has been reported that destabilization of lignin was able to promote more hydrolysate or gas production in many kinds of waste digestions, i.e. fruit brunch, maize, sunflower cake, wheat stalks, and rice straw. In this study, about 36.8%, 26.2%, and 8.3% of hemicellulose, cellulose, and lignin, respectively was found in raw Napier grass. These fractions were affected differently by pretreatment and ensiling. After the preparation process, the solid composition of grass was solubilized. An analysis of residues composition found that less complexed fraction liked hemicellulose was degraded simultaneously in all conditions. These were 5.7%, 39.1% to 53.9%, and 23.7% to 32.7% of hemicellulose which was reduced after ensiling, alkaline and alkali-thermal pretreatment, respectively. However, different variations of cellulose compositions in the samples were observed. About 15.6% of cellulose was reduced after ensiling, however, many pretreated samples trended to promote more cellulose concentration. These increase by approximately 1.8% to 2.2%. For more complex compositions such as lignin, it was found that only 4.2% was changed after ensiling. While approximately 50.1% to 62.3% or higher reduction was promoted after alkaline pretreatment, particularly ones which were heated by the autoclave (68.0%). It was noticeable that alkali-thermal pretreated samples contained lower concentrations of lignin in dry solid fraction for 2.3% to 2.5%. This was also observed for residue biomass from which about 38.8% to 39.7% of lignin was removed. An increase in raw grass soaking time from 24.0 h to 48.0 h also promoted a slightly higher degree of lignin destabilization which increased to about 12.2% as well. Whereas the supplementation of heat in residue biomass was able to enhance the production of SCOD to 45.2% to 55.2% compared to 0.102 kg SCOD for the normal conditions. This result corresponded well to the other works; they stated the benefit of biomass preparation was promoted after alkaline pretreatment [24]. The initial soluble products were determined by diluting 1.0% of the total solids in tap water. The result depicting the slight variation was promoted. The pH of grass samples varied between 4.0 to 7.5 in all samples. Raw grass and silage provoked a slightly more acidic condition than the others. Consequently, a pH of about 4.0 was found in silage, while higher values of 4.4 were found in raw grass. The different pH was also observed in the pretreated samples, where the adjustment was applied. Moreover, the soluble fraction in terms of SCOD and tVFA were differently promoted. About 2.5 kg SCOD/m3 to 6.6 kg SCOD/m3 and 2.2 kg tVFA/m3 to 3.8 kg tVFA/m3 were generated initially. The different characteristics of grass and silage had been reported previously. This variation was influenced by many factors such as cutting age [8, 14].

3.2. LBRs Performance

3.2.1 Production of SCOD and tVFA

The solubilization of grass biomass under different treated conditions, depicted in terms of produced soluble products such as SCOD and tVFA in leachate, are summarized in Table 3. The results show that grass solubilization in leached bed acidification was related significantly to the ensiling and alkaline soaking process. An increase in SCOD was more rapid in alkaline pretreated biomass than ensilaged and raw biomass digestion. In general, the production of soluble products was increased from the initial concentration of 2.5 kg/m3 to 6.6 kg/m3 in all reactors to the maximum concentrations of around 8.1 kg/m3 to 19.6 kg/m3. Alkaline pretreated grass samples in reactor B, C, and E generated higher SCOD concentration for 6.4 kg/m3 to 8.7 kg/m3 and productivity of 0.121 kg SCOD, 0.131 kg SCOD, and 0.157 kg SCOD compared to 0.102 kg SCOD or 5.4 kg/m3 of the untreated biomass (reactor A). Moreover, rapid solubilization promoted the maximum concentration of SCOD within 3.0 d to 6.0 d for reactor C and E, while about 6.0 d to 12.0 d were needed for the others. These soluble products contained 39.5% to 76.0% of tVFAs. Similar patterns of volatile fatty acid related well with the production of SCOD. Pretreatment by alkaline soaking influenced significantly the acid production yield. The increase in tVFA production was promoted. It was found that about 6.9% to 16.1% of tVFA increased compared to 0.051 kg tVFA of raw grass acidification. It was found that about 6.92–16.14% of tVFA increased compared to 50.62 g tVFA of raw grass acidification. Similar findings were also stated in ensiled sorghum (Sambusiti et al. [16]) or leaf waste (Chaiyapong and Chavalparit [14]) digestion. An increase in alkali soaking time also promoted more productivity. In this study, about 5.5% of SCOD and 9.2% of tVFA was found. For silage, about 10.2 kg/m3 or 0.73 kg SCOD/kg VSadded was promoted in reactor D. This was increased to about 11.5% compared to 0.113 kg SCOD in raw grass. Although similar productivity was obtained for the ensiled biomass, it was found that more rapid digestion which maximized acidic concentration was achieved within 6.0 d compared to 12.0 d of raw grass digestion.

The previous findings also stated the importance of pretreatment. McEniry et al. [19] concluded that grass ensiling was a main preprocess able to promote more degradation and use as a pretreatment method for cellulosic feedstock digestion. In this study, the production of tVFA was increased to about 9.2% and 18.3% for different for raw grass for 24.0 and 48.0 h-soaked samples. Similar results were also found for silage and residues. It was worth noting that supplementation of heat in alkaline thermal pretreatment enhanced the degradability of grass residue by about 16.5% to 21.6% when SCOD from manure was neglected. The addition of manure only generated about 0.12 kg tVFA/kg VSadded at 20.0% inoculum. The same findings were also stated by Xie et al. [4]. They found that the production of soluble products of ryegrass digestion was increased with increased incubation time. Furthermore, it was also found that alkaline pretreatment affected significantly to grass degradation. The soaking in 3.0% of NaOH was a benefit to digestion which was able to increase about 19.6% to 28.6% of acidic production. The rapid rate of digestion in terms of tVFA production was also promoted. Likewise, Chaiyapong and Chavalparit [14], the alkaline pretreatment of Acacia leaves increased significantly methane production of 0.098 m3/kgVSadded to 0.210 m3/kgVSadded or a 2.0 times increase. Considering the rate of tVFA production, the results indicated the benefit of ensiling and pretreatment on acid production of grass. An increase of production rate of about 6.3% was found for ensilaged grass and 9.6% to 15.9% for alkaline pretreated grass. While alkaline pretreatment of sunflower stalk removed about 22.0% of lignin and the production of soluble product was increased subsequently by 22.5% [25]. Similarly, about 21.0% of SCOD was also increased after alkaline pretreatment of grass silage [6]. It was worth noting that hemicellulose was preferred components by means of its more easily to be degraded compared to cellulose and lignin.

Considering the enhancement of residue degradation in reactor G and H, it was found that an additional treatment by re-soaking of residue in alkali-thermal condition benefited the biodegradation of residue in the leached bed process. The different residue sources of raw and silage exhibited a slight difference in soluble COD products which were 0.077 kg SCOD and 0.085 kg SCOD. These were increased to about 45.5% to 55.2% compared to raw and silage digestion directly. It was noticeable that the pretreatment of raw and silage by alkaline soaking promoted about 0.121 kg SCOD to 0.131 kg SCOD, and 0.115 kg SCOD which contained 54.5% to 65.6%, and 57.6% of tVFA, respectively. These productions were also increased to about 18.8% to 28.7% and 17.5% when compared to raw and silage ones. For the post alkaline thermal pretreatment of residue, when the soluble COD of manure was neutralized, it was found that the direct pretreatment obtained lower productivity of soluble product for 5.1% which was 0.148 kg SCOD. Raw grass with thermal pretreatment generated 0.157 kg SCOD, whereas the production of SCOD in raw grass was 0.102 kg. This was increased consequently by about 0.055 kg SCOD or 54.0% increase after the alkali-thermal process. Furthermore, it was reported that the hydrolysis and acidification performance of solid feedstock depended closely on substrate type and composition. Moreover, for alkaline and alkali-thermal pretreatment, the level of temperature and soaking time is critical also. For example, Appels et al. [2] obtained a negligible increase of biogas production from sludge pretreated by 20.0 times improved when extending the soaking time from 30.0 to 60.0 min.

In Fig. 1, the SCOD production rate depicted in terms of the daily and specific production rate are shown. It was found that alkaline pretreatment promoted more solubilization rates which were 5.1 g SCOD/d to 8.8 g SCOD/d or 0.039 kg SCOD/kg VSadded to 0.053 kg SCOD/kg VSadded, respectively. The increase in soaking time and supplementation of heat increase the rates for 19.9% to 30.4% or from 5.11 g SCOD/d to 6.38 g SCOD/d and to 7.34 g SCOD/d for raw, 24.0 h-soaked and 48.0 h-soaked samples, respectively. While about 5.10 g SCOD/d to 8.80 g SCOD/d was increased for raw and alkali-thermal pretreated grass. A similar finding was also found for silage. However, for the residue digestion, it was found that only 5.5% of the solubilization rate was different. There were 4.34 g SCOD/d (0.048 kg SCOD/kg VSadded) and 4.59 (0.045 kg SCOD/kg VSadded) for residue from raw grass and silage digestion, respectively. In consequence, not only rates were regulated, but the duration of acidification which promoted maximum concentration was reduced also, about 3.0 d to 6.0 d shorter. In the case of ensiled grass, the lower production of about 0.098 kg SCOD was found. However, the specific productivity was still increased by 6.6% or from 0.56 kg SCOD/kg VSadded to 0.60 kg SCOD/kg VSadded. The reason may be that the volatile composition was missing during the process. Therefore, the low volatile solid was significantly loaded, a stable soluble product was found to be generated. About 3.2% of acid was reduced, from 0.058 kg to 0.054 kg. This finding should be carefully considered in practical operation.

3.2.2. Leachate’s profiles

In Fig. 2 the quality of leachate depicted as VFAs profiles from each LBRs is shown. It was found that HAc, HPr, and HBu were the main compositions promoted in all conditions. While HBu and HVa were slightly varied to each pretreated condition. At the maximum SCOD promoted of each LBRs, these main acidic concentrations accounted for 39.5% to 76.0% and 11.3% to 16.6%, 6.6% to 24.3% for HAc, HPr, and HBu, respectively. The higher concentration of HAc had been reported as beneficial to further digestion and methane production. The increase in VFAs production was differently observed. These corresponded well with leachate productivity. The different treatment seemed to promote slightly different acid composition with different degradation rates. Similar patterns of leachates composition were promoted. VFAs profile of each LBRs depicted as individual composition and percentage of each fraction are showed. It was found that at a maximum fatty acid concentration of each LBRs varied between 4.0 kg/m3 to 10.8 kg/m3. This variation was differently affected by treatment conditions. More HAc concentration and its fraction were promoted in reactor A, C, and F which were 40.0% to 70.0% of the SCOD product. It was found that the high level of the alkalinity promoted preferably condition that maximized the production of tVFA. While the promotion of HPr and HVa production was found at high F/X ratio [26]. In this study, a slight different finding was found. The production of VFAs was differently varied by the initial characteristic of grass biomass and internal condition while about 6.6% to 24.3% of HBu was also found. It was noticeable that the pretreated grass biomass contained normally high basic contaminant in the sample. Although all sample was adjusted its pH to 7.0 to 7.5, the different condition still observed in each tank. The high organic constituent bearing in feed influent the production of tVFAs. The similar finding also stated by Parawira et al. who found that the increase of organic loads of potato waste, the similar patterns of VFAs except HBu was observed. The increase of VFAs production corresponded with solid loaded. While, the key compositions were HAc, HBu, HPr, respectively.

3.2.3. The degree of solubilization and acidification

The obtained results depict that ensiling, and pretreatment of Napier grass promoted different effects to grass solubility. The variation on acid production was found from 0.098 kg SCOD to 0.102 kg SCOD to for raw to silage grass and 0.121 kg SCOD to 0.157 kg SCOD for alkali-pretreated. The higher rate depicted as the maximum concentration of acid was promoted rapidly in treated conditions and lower reaction time was needed for degradation. There were 6.4 g SCOD/d, 7.3 g SCOD/d, and 8.8 g SCOD/d in reactor B, C, E compared to 5.1 g SCOD of raw grass (A). Moreover, the increase in soaking time in reactor B promoted more productivity which increased by about 7.8%. Whereas, heat supplementation of an alkaline pretreated sample of E and G, and H also promoted more soluble products production of 54.0%, 45.2% and 55.2%, respectively.

In addition, the estimation was conducted to determine the degree of solubilization and acidification in terms of SCOD/TCOD and CODVFA/SCOD, respectively. The results are shown in Fig. 3. It was found that about 51.5% to 80.7% of grass was solubilized in the leached bed process. These resulted consequently to about 23.2% to 48.4% of the degree of acidification. The treatment condition seemed to be a major influencing factor on the solubilization. The higher degree was promoted in all alkaline pretreatment conditions, particularly alkali-thermal processes. The solubilizations of raw grass were increased from 51.5% to 58.6%, and 61.1% for raw grass, 24.0 h alkaline soaked grass, 48.0 h alkaline soaked grass, respectively. While the maximum degree of solubilization was promoted at the alkali-thermal pretreated condition. These promoted about 80.7% and 48.4% of solubilization and degree of acidification, respectively. The increase in the soluble product in residue digestion after the post-treatment condition was also observed. About 40.6% to 45.6% of SCOD was increased. Similarly, Xie et al. [4] concluded that hydrolysis yields, acidification yields and the degradation of lignocellulosic materials can be increased by the addition of inoculums and dilution of leachate. However, an increase in the OLR reduced the hydrolysis and acidification yields.

3.3. Digester’s Stability

3.3.1. Variation of pH, Alk and tVFA

To consider the stability of each LBR, the change of controlled parameters from the variety of intermediate products was also monitored. In Table 3, the variation of pH, Alk, tVFA of discharged leachate and produced gas production are also summarized. It was found that those parameters related closely to the different initial operation conditions by means of ensiling and pretreatment which promoted different degradation. Not only the acidification rate and soluble products were differently generated, but the digester stability was also observed. The variation of pH was less significant. The higher fluctuations were promoted typically within the first two weeks. The higher production of acids in the pretreated biomass sample of reactor C and E also promoted more variation of pH. The average pH of each LBR was slightly different. The reactor fed with pretreated biomass seemed to depict more pH ranging from 6.6 to 6.9. However, the lower pH values of 5.9 to 6.1 were found in this period. However, after dilution, the system performed properly, the balance of pH and load was maintained. Moreover, the variation of pH corresponded to acid production which mainly occurred within the first two weeks of incubation. The fluctuation of pH of each LBR varied. Similar to pH, the system alkalinity and tVFA also varied according to the produced acidic products. For the first two weeks, the variation was high. The surplus substrate in this step promoted the acidic products. These ranged from 3.9 kg tVFA/m3 to 10.8 kg tVFA/m3. It was found that the pH was the main operational parameter and may vary during acidogenesis for 5.0 to 7.0 when no buffering condition was applied. The final pH value depends on the initial characteristic and internal environmental conditions existing in digester. Sambusiti et al. [21] found that alkaline pretreatment can have a beneficial effect both in enhancing methane production by an increase of 25.0% of methane production and promoting more stability to the digestion process. The addition of NaOH allowed maintaining high alkalinity in the system, limiting pH drops and avoiding the destabilization of the anaerobic digestion process.

3.3.2. Gas production

In the acidification tank, the production of leachate rich VFAs was desired. The limit of performing methanogenic populations was expected. Herein the produced acidic leachate was regularly diluted and discharged out of the digester. Thus, the limitation of retention time and substrate availability was properly promoted. From the results obtained in Table 3, it depicted that methanogenic performance of each LBR was rather low. Only about 0.6 to 11.2% of methane was found in produced biogas. The averaged methane composition of each tank was varied also which were 4.9%, 2.1%, 3.3%, 6.9%, 3.7%, 3.9%, 1.8%, and 1.3% for A to H, respectively. The lower methanogenic performance was observed in residue digestion which was 1.3% to 1.8% of methane production. The daily production of biogas in each LBRs was averaged about 0.48 L/d to 2.61 L/d. This was initially increased with time and decrease after the maximum digestion was promoted normally within two weeks. The maximum production of soluble products liked SCOD also generated a high production of biogas. The different pretreatment promoted slightly different production of biogas and its composition. It was also noticeable that the methanogenic performance of reactor A and D fed with raw and silage grass was better than others particularly alkaline pretreated ones. The increase in methane of 6.5% to 11.3% was observed. This initially pre-hydrolyzed biomass depicted more proper conditions for acidic digestion, while only about 0.6% to 3.6% was found in residues digestion. It was also found that an organic fraction was initially lower than the others. A similar finding was also observed. Ma et al. [27], reported that the methanogenic activity in an acid tank for maize digestion was minimized naturally by the pH fluctuation.

3.4. Solid and Lignocelluloses Degradation

The degradation of solid grass biomass and its cellulosic components after four weeks leaching in an LBR under different initial treatment conditions are shown in Fig. 4. It was found that the degradation of solid and cellulose and hemicellulose were similarly which increased with pretreatment process. However, the lignin composition was slightly decreased. This fraction was reported as hardly degraded in biological digestion. In Fig. 4, the maximum was 21.5% when alkali-thermal conditions were applied for raw grass biomass. In the acid production process, not only the generation yield was mentioned, the proper acid solution of acetic acid is mostly preferred. It was worth noting that the residue of grass biomass of each LBR initiated by different grass promoted different residues properties. The maximum solid reduction as well as hemicelluloses content was similarly found. The hardly degraded substances liked lignin was constantly found. The post application of these residues such as paper making, post digestion, and fiber support could be potentially considered. The results indicate that the different pretreatment promoted different characteristics of biomass relating to degradation efficiency. This was about 45.2% to 62.3 % of volatile solid was destroyed. It was relatively depicted that the higher VFAs generation seeded to promote more solid reduction. These were 53.2%, 45.6%, 62.2%, 55.3%, and 46.6 % for raw grass, silage, silage with 10.0%, silage with 20.0% inoculum and alkali-pretreated grass, respectively. A similar finding of Pensri et al. [28] stated that pretreatment with 3.0% (w/v) NaOH solution at 121°C for 60.0 min provided the highest lignin removal of 86.1% (w/w) and enriched cellulose fraction from 36.4% to 75.6%. The enzymatic hydrolysis was conducted by varying enzyme loading volume and total solid contents (TS) at pH 4.8, 50°C for 72.0 h. In fact, the pretreatment step is applied to improve biomass biodegradability by increasing the accessibility of holocelluloses to enzymatic degradations. Alkaline pretreatments are known to be efficient in delignification, fiber expansion and increase the pore size and accessible surface area. This led to an increase in methane production from sunflower stalks digestion by 29.0% to 44.0% [25].

4. Conclusions

Different preparations affected differently to grass characteristics and its digestibility in anaerobic LBR. Grass ensiling seemed to promote a slight effect on grass solubilization. The alkaline pretreatment increased more soluble products production which was about 13.6% to 18.0% and 56.6% of SCOD for with and without heat supplementation conditions. An extension of biomass soaking time and heat supplementation under alkali-thermal conditions of raw grass promoted more production of SCOD for 18.9% to 29.9% and 54.1%, respectively. While about 45.5% to 54.4% of SCOD was increased after applied alkali-thermal pretreated residue. The higher reduction in solid biomass was found to be significant in all alkaline pre-treated samples, as well as lignin content. It could be concluded that both ensiling and alkaline pre-treatment increased differently the acidic leachate production from Napier grass biomass which ranged between 0.28 kg/kg VSadded and 0.26–0.52 kg/kg VSadded, respectively. Silage grass was seemly acidified more rapidly, however, the lower solubilized products were slightly promoted. The obtained results depicted the possibility of enhancing acids production via process regulation and pretreatment.

Acknowledgments

This research was financially supported by the Office of Higher Education Commission (OHEC) and the S&T Postgraduate Education and Research Development Office (PERDO)