Effect of the supernatant reflux position and ratio on the nitrogen removal performance of anaerobic-aerobic slaughterhouse wastewater treatment process

Article information

Abstract

Slaughterhouse wastewater (SWW) is characterized as one of the most harmful agriculture and food industrial wastewaters due to its high organic content. The emissions of SWW would cause eutrophication of surface water and pollution of groundwater. This study developed a pilot scale anaerobic-aerobic slaughterhouse wastewater treatment process (AASWWTP) to enhance the chemical oxygen demand (COD) and total nitrogen (TN) removal. The optimum supernatant reflux position and ratio for TN removal were investigated through the modified Box-Behnken design (BBD) experiments. Results showed that COD could be effectively reduced over the whole modified BBD study and the removal efficiency was all higher than 98%. The optimum reflux position and ratio were suggested to be 2 alure and 100%, respectively, where effluent TN concentration was satisfied with the forthcoming Chinese discharge standard of 25 mg/L. Anaerobic digestion and ammonia oxidation were considered as the main approaches for COD and TN removal in the AASWWTP. The results of inorganic nutrients (K+, Na+, Ca2+ and Mg2+) indicated that the SWW was suitable for biological treatment and the correspondingly processes such as AASWWTP should be widely researched and popularized. Therefore, AASWWTP is a promising technology for SWW treatment but more research is needed to further improve the operating efficiency.

1. Introduction

The global production of meat is projected to progressively grow until 2050 [1], which will represent an expected increase in the amount of slaughterhouse wastewater (SWW) requiring treatment [2]. SWW is characterized as one of the most harmful agriculture and food industrial wastewaters due to its high organic content [3]. The emissions of SWW would cause eutrophication of surface water and pollution of groundwater [4] due to its high organic carbon and nitrogen (N) compounds [5].

Chinese meat production has been consistently ranked the first place in the world since 1990. Unlike other countries, pork is the most consumed meat in China, which accounted for 63.6% of the total meat production [6]. Correspondingly, “Effluent standard of pollutants for meat processing industry (GB 13457-92)” was firstly established in the last century, which is updating in line with the enhancement for water environmental protection in China (000014672/2018-01201). In which, effluent limit of total nitrogen (TN) has been added. The permitted maximum concentration of effluent TN has been set at 25, 20, and 15 mg/L for enterprises that are existed, new-built, and in environmental sensitive areas, respectively.

Chemical oxygen demand (COD) and ammonia nitrogen (NH4 +-N) were the main concern contaminants in the previous lab and case studies. Combined anaerobic-aerobic processes were developed to reduce the corresponding COD and NH4 + as well as cost maintenance [1]. Alure-type wastewater treatment process (ATWTP) was firstly proposed in recent decades [7], which was improved as the enhanced alure-type biological system (E-ATBS) to enhance the biological nutrient removal and got the excellent performance [6]. However, E-ATBS has the very long processes, which would bring higher costs and staff requirements.

Consequently, the design of experiments (DOEs) is widely used to surpass the limitations of traditional experimental methods in terms of time, materials and the number of experimental trials [1, 8]. DOEs include central composite designs, Doehlert matrixes, and Box-Behnken designs (BBDs) [9], in which BBDs need the least runs to investigate per variation. DOEs have been employed successfully to optimize the operational parameters in wastewater treatment [1, 8, 10].

In this study, the E-ATBS was bravely shorted to the anaerobic-aerobic SWW treatment process (AASWWTP) in the light of the characteristics of SWW, which was consist of five-stage ABR and only one-stage biological contact oxidation (BCO) tank. A pilot scale AASWWTP was installed to investigate its COD, NH4 +-N and TN removal capacities. Therefore, the overall goal of this research was to investigate the applicability and removal and economic efficiencies of the developed AASWWTP. The specific objectives were to: (1) investigate the COD, NH4 +-N and TN removal capacities of AASWWTP at different conditions designed through the modified BBD; (2) investigate the influence of the supernatant reflux position and ratio on the TN removal performance; (3) evaluate and summarize the operating mechanism of AASWWTP; and (4) compare the TN removal performance and economic efficiency of AASWWTP with other published biological SWW treatment processes.

2. Materials and Methods

2.1. Experimental Set-up

The flowchart of the AASWWTP is shown in Fig. 1. AASWWTP consist of regulating tank (RT), ABR with four anaerobic alures (1A, 2A, 3A and 4A) and one anoxic alure (5A), BCO tank and clarifier successively.

The acrylic bioreactor contained one 108 L ABR reactor (23.4, 22.5, 21.6, 20.7 and 19.8 L for 1A, 2A, 3A, 4A and 5A, respectively) and one 24.0 L BCO reactor. The soft combined semi-soft packing filter was used in the BCO reactor as the microbial attachment. The structure of the packing filter was a double-ring large plastic ring, on which were pressed the aldehyde fibers and in which was fixed by the snowflake plastic branch (Fig. 1). The packing filter diameter was 100 mm. The spacing was 80 mm. The packing filter was connected in series through the central fiber rope. A composite packing filter with the total folding length of 3 m was placed in the whole BCO reactor.

2.2. SWW Composition

Synthetic SWW was prepared according to the real wastewater, which has been discussed in the previous study [6]. Synthetic SWW was prepared aimed to contain 2,000 ± 100 mg/L of COD and 160 ± 10 mg/L of TN by adding the fresh porcine blood and sodium citrate. Note that sodium citrate was not only used to adjust the C/N, but also to avoid the blood coagulation.

2.3. Experimental Design

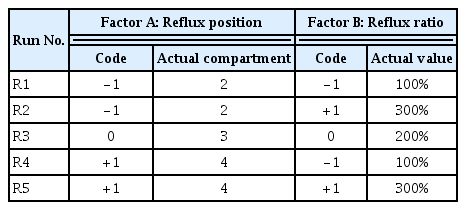

In this study, modified version design method according to BBD was applied to optimize the supernatant reflux position and ratio. According to the previous study [6] and the AASWWTP designed operation mode, the 2–4 anaerobic alures of ABR was chosen as the supernatant reflux position together with 100%–300% supernatant reflux ratios. Table 1 shows the modified BBD experiment including two variations and three levels. In this table, the independent variable levels were presented in terms of the coded levels. The coded values set for reflux position (A) and ratio (B) at three levels were: −1, 0, +1. The reflux positions were set at compartment 2, 3 and 4, and reflux ratios were 100%, 200% and 300%, respectively. Note that the minimum number of experimental runs was needed (only 5 runs in this study) through introducing the modified BBD, which is worth popularized.

To obtain the appropriate reflux position and ratio, six dependent parameters were analysed: COD, TN, NH4 +-N, NO2−-N, NO3−-N and pH.

2.4. Experimental Procedures

2.4.1. Experimental start-up

The inoculums were taken from the corresponding anaerobic, anoxic and aerobic tanks of slaughterhouse wastewater treatment plant in the previous case study [6]. Seed sludge was acclimated in the developed AASWWTP bioreactor for 30 d in the continuous mode with the pollution load of 500 g COD/m3/d and run at room temperature of 20 ± 2°C. The bioreactor was considered as start-up successfully when the effluent COD was kept lees than 80 mg/L, which was the effluent limit in the online draft of “Effluent standard of pollutants for slaughter and meat processing industry” (000014672/2018-01201).

2.4.2. Experimental run

To determine the appropriate supernatant reflux position and ratio, the AASWWTP bioreactor was run according to the modified BBD in Table 1. Two parallel samples for effluent were taken every 24 h. When the effluent COD and TN concentrations were stable (a p-value with a 95% confidence level; [11]), two parallel samples for influent, effluent and at different compartments were taken and analysis for COD, TN, NH4 +-N, NO2−-N, NO3−-N and pH. Experiments were repeated if there was a sample analysis error greater than 5%.

The inorganic nutrients of K+, Na+, Ca2+ and Mg2+ for microbial growth at the optimum TN removal condition was also detected to investigate the nutrient supply of SWW to microorganisms.

2.5. Analytical Methods

Water samples were taken from each stage and then filtered by 0.45 μm membrane before detection except for COD and TN. NH4 +-N, NO2−-N, and NO3−-N were measured using a spectrophotometer (DR6000, HACH, USA) according to the Chinese NEPA [12] standard methods, and the method detection limits (MDLs) were 0.035, 0.003 and 0.052 mg/L, respectively. K+, Na+, Ca2+ and Mg2+ were measured using a Metrohm ECO Compact IC Pro (Herisau, Switzerland) ion chromatograph. MDLs were 0.07, 0.13, 0.07 and 0.07 mg/L for K+, Na+, Ca2+ and Mg2+, respectively.

COD was measured through Lovibond mid-range kits with the MDL of 0–1,500 mg/L. TN concentration was measured using Hach TNT plus 827 test kit. pH was measured using a pH meter with calibrated electrode (FiveEosy Plus, Mettler Toledo, Switzerland; MDL: 0–14).

3. Results and Discussion

3.1. COD Removal

Average COD concentration and COD removal efficiency in each modified BBD study are shown in Fig. 2. COD was removed successively with the flow of SWW in the AASWWTP bioreactor. Moreover, the reflux position also played an important role in COD removal. For example, when the supernatant returned into the second compartment of ABR, ~50% COD was removed in this compartment.

Average of COD concentration, removal efficiency and pH level in each design study. The stages were influent from regulating tank, 1A, 2A, 3A, 4A, 5A and effluent successively.

From Fig. 2, it could be also found that all effluent COD concentrations were between 19 ± 1 and 43 ± 3 mg/L, which were much lower than the Chinese SWW discharge standard of 80 mg/L. COD removal efficiency was all higher than 98%, which was much higher than 80% of previous ATWTP [7] and similar to the upgraded enhanced alure-type biological system (E-ATBS) [6]. Hence, it could be concluded that the supernatant reflux can guarantee the efficient COD removal without adding more structures.

As known, discharge standard of pH was 6.00–9.00, which also reflected the suitable pH condition microbial growth [13]. In this study, pH at each modified BBD condition and each stage was all satisfied the above condition. However, the pH at each stage in the AASWWTP bioreactor showed the different trend at different modified BBD conditions. The supernatant reflux position and ratio affected the pH level simultaneously. This might be due to the introduced reflux affecting the microbial reactions of N removal, which would be fully described in section 3.2.

3.2. Nitrogen Removal

Average concentrations of NH4 +-N, NO2−-N, NO3−-N, TN and TN removal efficiency in each designed study are shown in Fig. 3. NH4 +-N and organic N formed the main contaminates of TN in SWW. Organic N firstly digested to NH4 +-N in the anaerobic stage. As shown in Fig. 3, NH4 +-N concentration increased most obviously in the first anaerobic stage of ABR (1A), which was also demonstrated that 1A played the roles of both hydrolysis-acidification and anaerobic digestion for organic matter simultaneously. NH4 + accumulated continuously until the supernatant returned compartment/alure and then decreased sharply at the corresponding alure due to partial denitrification (PD)-ANAMMOX [6]. After this alure, NH4 +-N concentration increased again slowly as the remainder organic N amination in the rest of ABR. Finally, NH4 +-N concentration decreased to lower than 0.50 mg/L at the aerobic stage of BCO reactor.

Average of N species and TN removal efficiency in each design study. The stages were influent from regulating tank, 1A, 2A, 3A, 4A, 5A and effluent successively.

NO2− and NO3− as the nitrification productions can be used as the source for PD-ANAMMOX [14]. However, different reflux conditions would lead to different amount of NO2− and NO3− accumulations in the final effluent. In this study, the highest NO2−-N and NO3−-N accumulation of 1.74 ± 0.01 and 61.00 ± 1.98 mg/L were detected at the conditions of R5 and R4, respectively. Hence, the supernatant returned to the forth compartment/alure would lead to the highest NO2− and NO3− by-products accumulation. The more forward the supernatant reflux position was, the lower NO2− and NO3− by-products accumulation would be gained. At the same time, it could be found that NO3−-N concentration in effluent was lowest at 22.62 ± 0.28 mg/L at the condition of R2 (reflux position at 2 alure and ratio of 300%).

As shown in Fig. 3, NO2−-N concentration through the whole anaerobic and anoxic stages in ABR was all lower than 0.02 mg/L. Correspondingly, NO3−-N concentration was lower than 10 mg/L. Unlike NO2−, NO3−-N concentration increased obviously at the reflux compartment/alure. This also can be used as the side validation of the analysis of PD-ANAMMOX as the main process for TN removal in the AASWWTP.

TN decreased slowly except for the supernatant reflux compartment/alure, which was similar to the COD removal in ABR but decreased more sharply. The supernatant reflux introduced the NO2− and NO3− as well as small amount of dissolved oxygen (DO), leading to the occurrence of PD-ANAMMOX [6]. In which, NO2− accumulated from partial nitrification in BCO reactor could be used together with the accumulated NH4 + in ABR for the ANAMMOX firstly as description in Eq. (1) [14]. After the supernatant reflux compartment, TN began to slowly increase except for R4, which was absolutely different to COD removal trend. Further study is needed as to analyse the microorganisms to find out the bacteria that lead to this slow increase.

Meanwhile, the reflux NO3− from BCO reactor and the produced NO3− from ANAMMOX process were used as the electron acceptor for microbial denitrification. As known, NO3− was the preferred electron acceptor over NO2− in microbial denitrification, expressed as NO3−→NO2−→N2 [15]. Hence, the intermediate product of NO2− would be accumulated during the PD process and be used as the reactant for ANAMMOX, forming the PD-ANAMMOX process to advanced TN removal. Moreover, some NO3− would be remained through the PD-ANAMMOX process according to Eq. (1), which was consist with the modified BBD experiment results. Almost all NH4 + and NO2− were removed and only some NO3− was accumulated at the conditions of R1, R2 and R3 (reflux position at 2 or 3 alure).

Effluent TN concentrations at R1 and R2 were the same as lowest level of 25 mg/L, which was satisfied with the Chinese SWW discharge standard for the existing enterprises. As known, lots of existing enterprises in China use the combined anaerobic-aerobic processes to reduce COD and NH4 + from SWW to match the existing “Effluent standard of pollutants for meat processing industry (GB 13457-92)” [6]. Hence, according to this study, it could be concluded that only the addition of supernatant reflux would lead to the objective of TN decrease. The existing enterprises can improve the SWW treatment plant only through the simple modification, which can use the minimum cost and ensure the effluent satisfied with the upcoming discharge standard.

Through the analysis of NH4 +-N, NO2−-N, NO3−-N and TN in the AASWWTP bioreactor at different design studies, it could be concluded that both R1 and R2 showed the excellent N removal capacity. Considering that the increase of reflux ratio would increase the operation cost, R1 (reflux position at 2 alure and ratio of 100%) was chosen as the optimum condition for N removal in AASWWTP. However, the further study is still need to optimate the supernatant reflux conditions more precisely.

3.3. Inorganic Nutrients Characteristics

K+, Na+, Ca2+ and Mg2+ as the main inorganic nutrients for microbial growth had also been detected in the optimum condition of reflux position at 2 alure and ratio of 100% (Fig. 4). As shown in Fig. 4, there is enough inorganic nutrients of K+, Na+, Ca2+ and Mg2+ in the synthesized SWW. But only Ca2+ decreased a little during the AASWWTP, whereas K+, Na+, and Mg2+ concentrations increased. This might be due to the inorganic nutrient utilization by microorganisms lower than the nutrient mineralization from porcine blood. As known, K+, Na+, Ca2+ and Mg2+ contents in the fresh porcine blood were 56, 56, 4, and 5 mg/100 g, respectively [16]. In which Ca2+ content was the lowest. Hence, only Ca2+ showed the decreased trend during the SWW treatment. Moreover, Na+ increased most obviously as the co-containing in the fresh porcine blood and sodium citrate. These results also indicate that the SWW is suitable for biological treatment and the correspondingly processes such as AASWWTP should be widely researched and popularized.

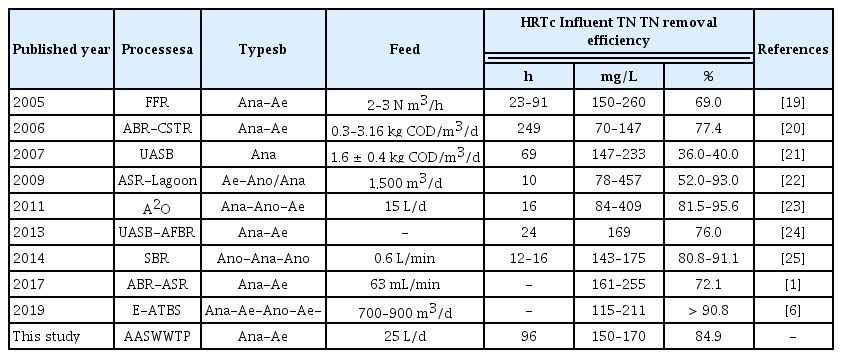

3.4. SWW Treatment Processes Comparison

Reducing COD and BOD concentrations in SWW is the main focus of the secondary biological treatment by removing soluble organic compounds at the beginning of lab and case studies [17]. However, N species in SWW would cause eutrophication of surface water and pollution of groundwater if SWW emissions without fully treatment [4]. Hence, biological nitrogen removal (BNR) process has been added together with COD removal in the secondary biological treatment processes. The biological processes for removing N species from wastewaters mainly included tradition nitrification/denitrification process, SHARON process (NH4 + is oxidized only to NO2− followed by denitrification), and ANAMMOX process [18].

Table 2 illustrates some published biological processes for TN removal from SWW in this century. There are lots of different and combined biological technologies used in SWW treatment. It could be concluded that combination biological processes and integrated systems always showed better TN removal efficiency. As shown in Table 2, Del Nery et al. used the simple anaerobic technology of UASB and got the TN removal efficiency of 36.0%–40.0% [21]. Other published technologies in Table 2 all used the combined biological technologies and got higher TN removal efficiencies, which were ranged from 52.0% to 95.6%.

Comparing to other published technologies, the AASWWTP showed relatively high TN removal efficiency, but not the highest. Considering the effluent standard of SWW in China, the developed AASWWTP was able to fit its requirement for effluent TN. In the previous study, the E-ATBS in case study has been fully discussed and showed the TN removal efficiency as high as 98% [6]. However, the E-ATBS contained much longer biological processes as hydrolysis-acidification tank (HT), anaerobic tank (1A) with 3 compartments, oxic tank 1 (1O1), oxic tank 2 (1O2), anoxic tank (2A), oxic tank (2O), clarifier, and sand filter successively. However, the AASWWTP developed in this study only had the shared anaerobic and anoxic tank of ABR and oxic tank of BCO. Comparing of AASWWTP and E-ATBS, the developed AASWWTP can reduce about 30%–40% cost through the following four aspects: (1) the number of oxic tank reduced from three to one, which would save about 33% electricity consumption for aeration; but the supernatant reflux would consume about 5% from that saving. (2) The reduced structures would save about 30%–40% land occupation; (3) the disposable cost for construction would save about 30%–40% simultaneously; and (4) less operating and maintenance costs were needed. Hence, on the basis of ensuring the effective removal of TN, the developed AASWWTP can greatly reduce the cost of capital investment and operation and maintenance. AASWWTP is a promising technology for TN removal from SWW. Further scientific calculation would be done in the next step study to confirm the accurate budget.

In addition, the combined biological and physicochemical processes have also been studied and utilized in the advanced N removal of SWW. Bohdziewicz and Sroka reported the combined activated sludge (AS)-reverse osmosis (RO) system for the treatment of SWW and gained a high COD and TN removal of 99.80% and 99.77%, respectively [26]. Bustillo-Lecompte et al. [27] developed a combined ABR-AS-UV/H2O2 process and reported up to 99.98% TOC and 82.84% TN removal efficiencies.

Although combined biological and physicochemical methods often got the high removal efficiencies, the simple biological processes were still gotten priority in the practical application considering to the relatively low operating costs, low requirements for operators and the environment friendly. Moreover, the development of biological processes also ensured the high TN removal efficiency. The developed AASWWTP in this study got the 85% TN removal efficiency, which showed a litter higher than the combined biological and physicochemical method of ABR-AS-UV/H2O2 (~83%) [27]. Hence, the biological processes for SWW treatment should be widely researched and popularized.

4. Conclusions

AASWWTP for advanced TN removal of SWW was developed and the optimum supernatant reflux position and ratio were investigated. COD could be effectively reduced over the whole modified BBD study and the removal efficiency was all higher than 98%. The optimum reflux position and ratio were suggested to be 2 alure and 100%, respectively. Effluent TN concentration was satisfied with the upcoming Chinese discharge standard for the existing enterprises of 25 mg/L. AASWWTP is a promising technology for SWW treatment but more research is needed to further improve the operating efficiency.

Acknowledgments

This research was financially supported by China Postdoctoral Science Foundation (Grant No. 2018M630245), the National Key Research and Development Program of China (Grant No. 2016YFD0501405) and Beijing Postdoctoral Research Foundation (Grant No. 2017-ZZ-137). The authors would like to thank the local slaughterhouse industry for the supply of seed sludge and fresh porcine blood.